Jan 24, 2019

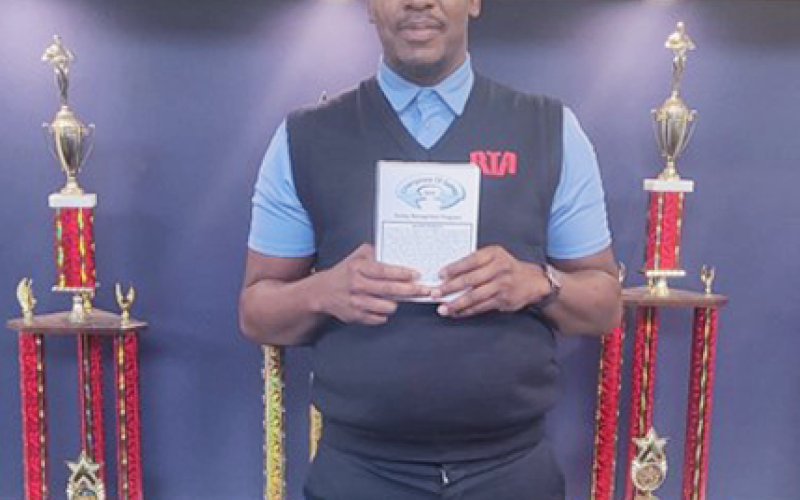

The trains don’t put themselves back together when something falls off the rails. Behind the scenes, it takes a small army of mechanics at the Rail Shop split between 3 shifts, working day and night to ensure you are transported to your destination safely. Rail Equipment Manager, Casey Blaze and his team work hard on maintaining RTA standards for you to have a safe, reliable, clean and courteous experience. On average, RTA serves around 7 million riders per year on the rail system. Without the continuous work of our mechanics to maintain and repair theses massive vehicles, keeping the rail fleet safe and reliable would be nearly impossible.

Initially, Casey started as a business analyst for RTA in 2012. As a district business analyst, you are exposed to all aspects of the district, including equipment, on-time performance, overtime, inventory, etc. Casey’s interest was especially piqued when it came to rail equipment. While earning his undergraduate degree in Finance, he worked as a car mechanic, so having a mechanical background has helped him to have a greater understanding of his shop from the very beginning.

Casey, who also has a Master’s degree in Business, was promoted to Rail Shop Supervisor. He contributes much of his success at RTA to his mentor, John Fedikovich, who was the Rail Transportation Manager at RTA at the time. He explains how once he became interested in something, John would make sure to teach him everything he knew about it. Together, they were an unlimited source of knowledge and experience. John helped fuel Casey’s passion for rail and describes Casey as a “real bright guy that was like a sponge and wanted to learn more about anything and everything. His thirst for knowledge became a passion.”

“Passion is an important aspect of this industry because it’s not the easiest career to have. Employees must have a thorough understanding of track design, electrical theory, automotive technology, and heavy equipment repair.” Rail Shop employees go through extensive training programs ranging in training time of 24 to 30 months. Currently, the RTA Rail Shop employs 84 mechanics across 13 classifications. They range in experience and expertise.

While speaking in depth with machinist Steve Novak, we had the opportunity to expand our knowledge of the rail shop. Steve has been in the trade for over 40 years and uses his experience wisely here at RTA. Steve explained how he incorporates previously used parts from rail to make new parts and track equipment all together. Building parts and equipment can take anywhere from a few hours to a few days, depending on the issue or intricacies at hand. Having Steve as a machinist is priceless for the rail shop, considering Steve can make just about anything from old parts or raw materials. The largest mechanical equipment he ever built was an engine mount for a locomotive.

While repairs can take anywhere from 30 minutes to 2 months, different defects require different repair times. “Some parts are made in hour, some need to be are reverse engineered, and others are specially ordered globally, such as Australia and China just to name a few,” Casey said. We have a wide variety of experts at RTA, and the amount of work they can complete is amazing. Currently, there are multiple parts being refurbished on both heavy and light rail trains, such as brake units, valves and line breakers. All trains get inspected every 30 days with the exception of a defect, which can happen in between inspections. It can take up to 6 months for a part to come in, so Casey stays on the ball by forecasting usage and alerting Inventory of items which will be hard to source months in advance.

While Casey is a busy man, he spends much of his time traveling to Pennsylvania for business but enjoys being in his own shop. Additionally, Casey eventually wants to make his way to Philadelphia to visit the Southeastern Pennsylvania Transportation Authority (SEPTA). When he’s not traveling, Casey enjoys spending time with his wife, Martina and young children.

Altogether, he works day and night to make sure our trains are safe and reliable for all of us. Casey’s loyalty and hard work ethic has been valuable and much appreciated throughout the years here at RTA. We would all like to thank Casey for his hard work and leadership!